□□G58-□C series

Explosion-proof illumination (power) distribution box (power maintaining socket box)

1. It is widely used in flammable and explosive gas environment such as oil exploitation, refining, chemical industry, offshore oil platform, oil tanker, etc. It is also used in flammable dust places such as military industry, port, grain storage and metal processing;

2. Applicable to Zone 1 and Zone 2 of explosive gas environment;

3. Applicable to IIA, IIB, IIC explosive gas environment;

4. Applicable to areas 21 and 22 of flammable dust environment;

5. Applicable to the temperature group is T1 ~ T4 / T5 / T6;

6. Mainly used for power distribution of temporary or mobile jobs

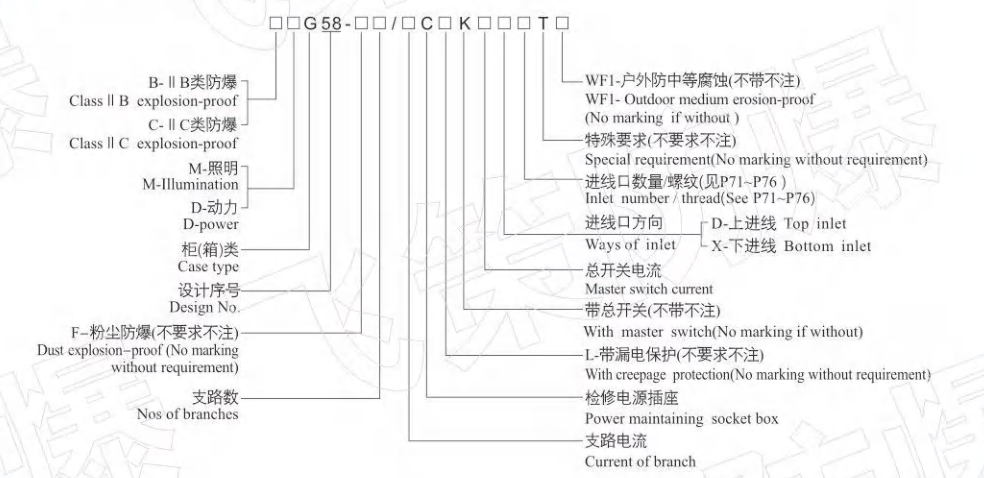

Model Implication

Features

1. The product structure mainly consists of cover, housing, explosion-proof latch, built-in circuit breaker or explosion-proof circuit breaker, and terminal blocks.

2. The component cavity is flameproof, the wall thickness is up to 12mm, and the inlet cavity is increased in safety. The modular combination between the cavities, the explosion-proof chambers are not connected to each other, reducing the net volume of the single cavity, thereby eliminating the overlap of the explosion pressure and enhancing the explosion-proof performance of the product.

3. Adopting the patented technology of the combined explosion-proof distribution box independently developed, the modular design and combination of the distribution box makes the whole distribution box structure more compact and better in use effect; any combination of each circuit can be required according to requirements. The earth has the configuration requirements for power distribution equipment in different places.

4. After removing burrs and high-speed shot blasting by industrial robots, the advanced automatic high-pressure electrostatic spray and heat-curing line technology is adopted. The plastic layer formed on the surface of the shell has strong adhesion and good anti-corrosion ability.

5. Internal moldable circuit breaker, high-breaking miniature circuit breaker, indicator light, button, instrument and other components, and other components can be added according to user requirements. Outdoor products can be equipped with rain cover according to user requirements.

6. The socket has a variety of specifications for the user to choose. A circuit breaker with a leakage protection function installed in the front stage.

7. The explosion-proof socket can be padlocked, and it can be locked with a padlock when not in use, effectively preventing accidental operation by others.

8. The plug and the socket are made into an electrical interlocking structure. After the plug is inserted, the rotating sleeve on the plug rotates clockwise by a certain angle, and the switch in the socket is closed, and the latch cannot be pulled out. Otherwise, the sleeve is rotated counterclockwise by a certain angle. The switch is disconnected before the plug can be pulled out. The socket is provided with a protective cover. After the plug is pulled out, the protective cover shields the socket to prevent foreign objects from entering.

9. The sealing strip adopts two-component polyurethane primary casting foaming process, which has high protection performance.

10. All exposed fasteners are made of stainless steel.

11. The cable incoming direction can be made into the up and down form according to user requirements.

12. The inlet and outlet ports usually use pipe threads to configure the cable clamping and sealing device. They can also be made into metric thread, NPT thread, etc. according to the requirements of the user's site.

13. Steel pipes and cable wiring are available.

14. The installation method is generally hanging type, and it can be used as an established type, a seat type or a power distribution cabinet when special requirements are required.

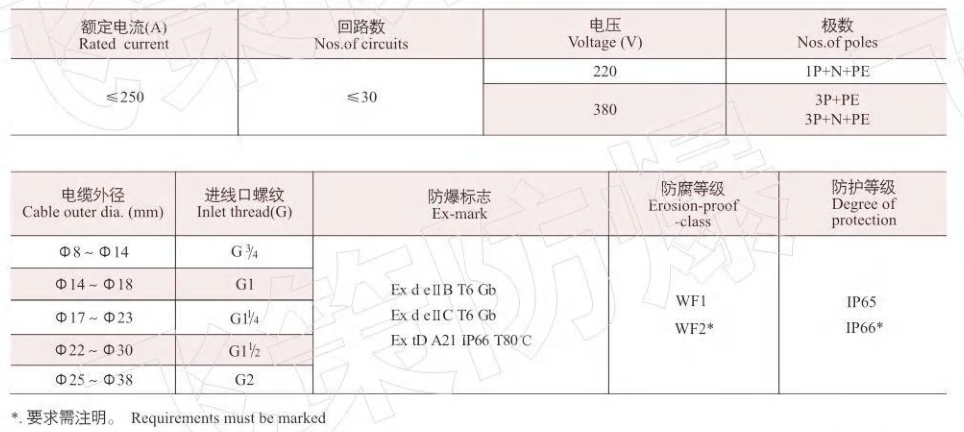

Main Technical Parameters

Order Note

Please indi cate its QTY, voltage, current, inlet QTY, inlet ways and size. If the outlet is necessary, please note its QTY and size. If it is with switch, please note its current and poles. In general, the user needs to provide an electrical schematic.