BF 2 8159-g series

Explosion & corrosion-proof illumination (power) distribution box

1. It is widely used in flammable and explosive gas environment such as oil exploitation, refining, chemical industry, offshore oil platform, oil tanker, etc. It is also used in flammable dust places such as military industry, port, grain storage and metal processing;

2. Applicable to Zone 1 and Zone 2 of explosive gas environment;

3. Applicable to IIA, IIB, IIC explosive gas environment;

4. Applicable to areas 21 and 22 of flammable dust environment;

5. Applicable to corrosive gases, moisture, and high protection requirements place;

6. Applicable to the temperature group is T1 ~ T6;

7. Perform overload, short circuit and protection on the controlled circuit and make separate points Lighting (power) switch for branch lines.

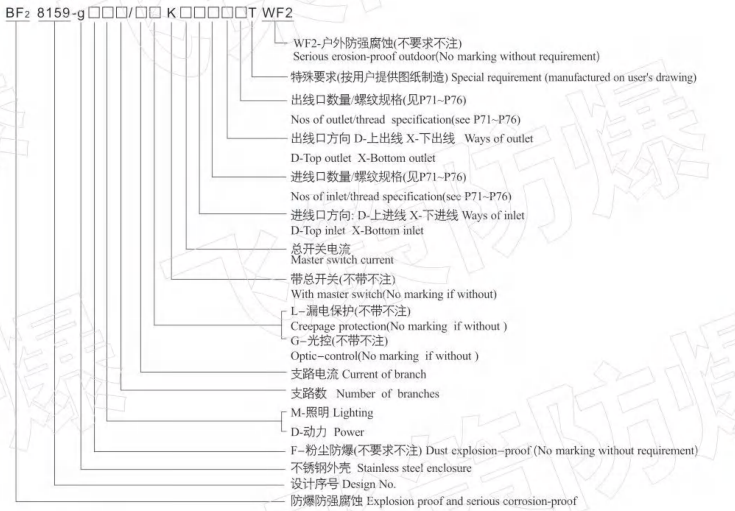

Model Implication

Features

1. The outer casing is made of stainless steel, which has beautiful appearance, corrosion resistance, impact resistance and good thermal stability.

2. Adopting the patented technology of the combined explosion-proof distribution box independently developed by the company, the modular optimization design and combination of the distribution box make the whole distribution box structure more compact and better in use effect; any combination of each circuit can be required according to requirements. Greatly, the configuration requirements for power distribution equipment in different places.

3. The industry's first and most recently developed large-scale (current) flameproof single-circuit breaker module (250A, 100A, 63A Ex components) can meet the supporting use of the increased safety stainless steel distribution box.

4. Built-in flameproof components. The assembled structure between the cabinets can be freely selected; the volume is small, neat and beautiful, and the installation space is small; the weight is light, and the installation and maintenance are convenient.

5. There is a special operating mechanism on the cover plate to achieve full-close operation. Padlocks can be added according to requirements to avo- id misuse. The product can also operate normally under harsh conditions, ensuring the personal safety of the user.

6. The main switch and sub-switch operation panels are clearly distinguishable for easy on-site identification.

7. All exposed fasteners are made of stainless steel.

8. Cable in and out of the line, according to user requirements can be made up and down, down and down, up and down, down and up and other forms.

9. The inlet and outlet ports are usually made of pipe threads, and the cable clamping and sealing device is arranged. It can also be made into metric thread, NPT thread, etc. according to the requirements of the user's site.

10. Steel pipes and cable wiring are available.

11. For outdoor use, the rain cover can be configured according to user requirements.

12. The installation method is generally hanging type, which can be established, seat type or power distribution cabinet when special requirements.

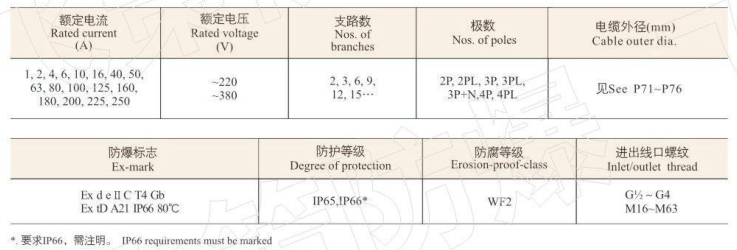

Main Technical Parameters

Order Note

1. Accord with the model implication's rules to select regularly, and Ex-mark should be added behind model implication;

2. If there are some special requirements, it should be pointed as ordering.