SW-10 series

Explosion-proof illumination switch

1. It is widely used in flammable and explosive gas environment such as oil exploitation, refining, chemical industry, offshore oil platform, oil tanker, etc. It is also used in flammable dust places such as military industry, port, grain storage and metal processing;

2. Applicable to Zone 1 and Zone 2 of explosive gas environment;

3. Applicable to IIA, IIB, IIC explosive gas environment;

4. Applicable to areas 21 and 22 of flammable dust environment;

5. Applicable to the temperature group is T1 ~ T4 / T5 / T6;

6. As a control switch for lighting fixtures or small electrical equipment, when installed There should be pre-level protection.

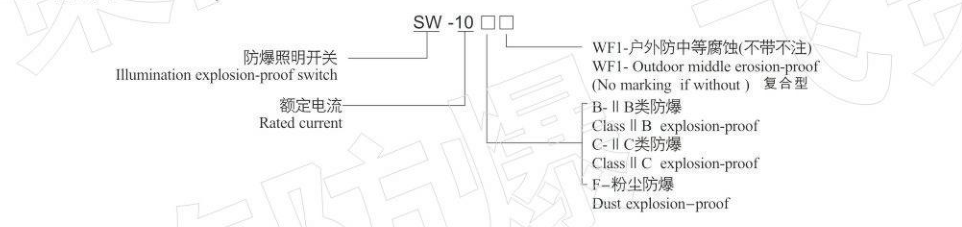

Model Implication

Features

1. The outer casing of the product is cast aluminum alloy ZL102. The product shell adopts one-time die-casting process, the surface is smooth, the appearance is beautiful, the internal structure is high in density, the impact resistance is strong, the shell has good anti- explosion performance, and the product has a permanent “Ex” explosion-proof mark.

2. After the surface of the product is deburred by industrial robots and high-speed shot blasting, the advanced automatic high-pressure electrostatic spray and heat-curing line technology is adopted. The plastic layer formed on the surface of the shell has strong adhesion and good anti-corrosion ability.

3. The product is divided into two types of explosion-proof type: explosion-proof casing and increased safety casing. The explosion-proof casing is equipped with HZ10 combination switch, and the increased safety type is equipped with explosion-proof switch.

4. The sealing strip adopts two-component polyurethane primary casting foaming process, which has high protection performance.

5. All exposed fasteners are made of stainless steel.

6. Steel pipes and cable wiring are available.

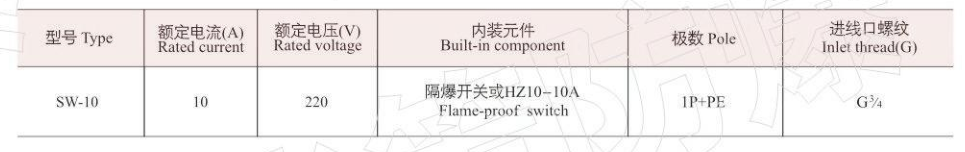

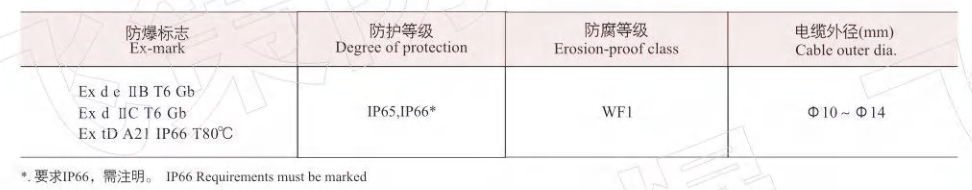

Main Technical Parameters

Order Note

1. Please indicate its size, Ex-mark and quantity according to model implication;

2. User must use flame-proof cable entry device for class ⅡC